Business Transformation at Pupuk Indonesia

To achieve its long term goal, Pupuk Indonesia and its subsidiaries continuously transforms its business by focusing on five strategic pillars, including: customer focus, research and innovation driven, supply chain and operational excellence, feedstock security and optimization, as well as corporate sustainability and circular economy.

As one big family, we collaborate to produce innovations that deliver value to our business, spanning from the factory floor to our end customers. By leveraging the latest technology, we always strive toward our readiness for industry 4.0.

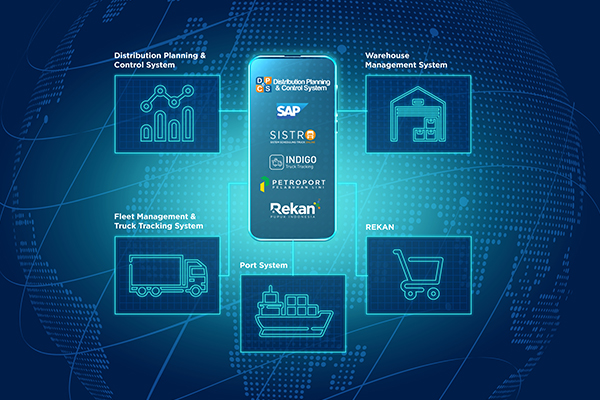

Smart Distribution Ecosystem – INDIGO

Pupuk Indonesia, along with its subsidiaries, built a smart distribution platform called Integrated Distribution and Logistic Optimization (INDIGO) which was combined from the best applications of each distribution function in each member company, such as inter-warehouse transactional system, distributor ordering system, port management system, truck queuing system and fleet management system.Those systems are monitored in a smart distribution dashboard called the Distribution Planning and Control System - DPCS

Last Mile Digitalization with Retail Management System – Rekan

"Rekan" which literally means partners, is a merchant app that will ease kiosks in doing transactions for both subsidized and commercial fertilizers, managing inventory, as well as transaction monitoring and tracking. In addition, it is integrated with payment gateway and data analytics.

Renewable Energy (Green & Blue Ammonia)

Pupuk Indonesia initiated a decarbonization roadmap to support the government's Net Zero Emission program. We are also focusing in the clean energy business with carbon capture facilities and planning to develop green hydrogen pilot plant in Lhokseumawe, Aceh, Indonesia.

Insitu Balancing on Rotating Machinery (Petro Balancing)

Petro Balancing is a smartphone application used to calculate and resolve the unbalance condition of rotating equipment. It is very simple to use, comes with accurate result and can be used for learning tool to understand step-by-step balancing process.

Virtual Reality - Ammonia, Urea, NPK

To increase the competence of plant operators, Pupuk Kaltim and Petrokimia Gresik have developed a VR-based learning platform. The platform succeeded in increasing the effectiveness of the learning process by addressing the limitations of time, place and learning materials..

Smart Production - PKT

The implementation of smart production in PT Pupuk Kalimantan Timur integrates various information related to the production process such as factory operational data, equipment health, and production area environment. The integration forms big data, which is easily accessible, thus creating a digital ecosystem that can support company activities to be more efficient.

Smart Production - PSP

In PT Pupuk Sriwidjaja Palembang, smart production is the implementation of digital transformation 4.0 in the production process. IPD (Interactive Process Display) Smart Production is able to read data from industrial automation and control equipment with various communication protocols to be brought to the control system and processed into digital data.